A Three-Pronged Approach

Problems come in different flavours

The easiest problems to solve are those that we can define or describe. They can be huge projects to implement the solutions, but they are relatively straightforward to figure out. These types of problems really fall into three categories:

1) Simple problems: the nature of the problem and the solution are known. These can be very large problems but their beginning and end is defined and the steps to complete the tasks are all defined.

2) Complex problems: the problem is known but the solution is not known and must be worked out, or the solution is known and readily available but the problem has not been defined. For example, we do not need to know how gravity works to be able to use the effects of gravity all the time.

3) Complicated problems: neither the definition of the problem nor the solution is known. How familiar this is! The baby is crying and has a fever. I don’t know what the problem is and I don’t know how to fix it. The usual approaches are 1) find an expert who can help (go to a doctor) or 2) make a “best guess” and monitor the symptoms of the problem to see if you guessed right.

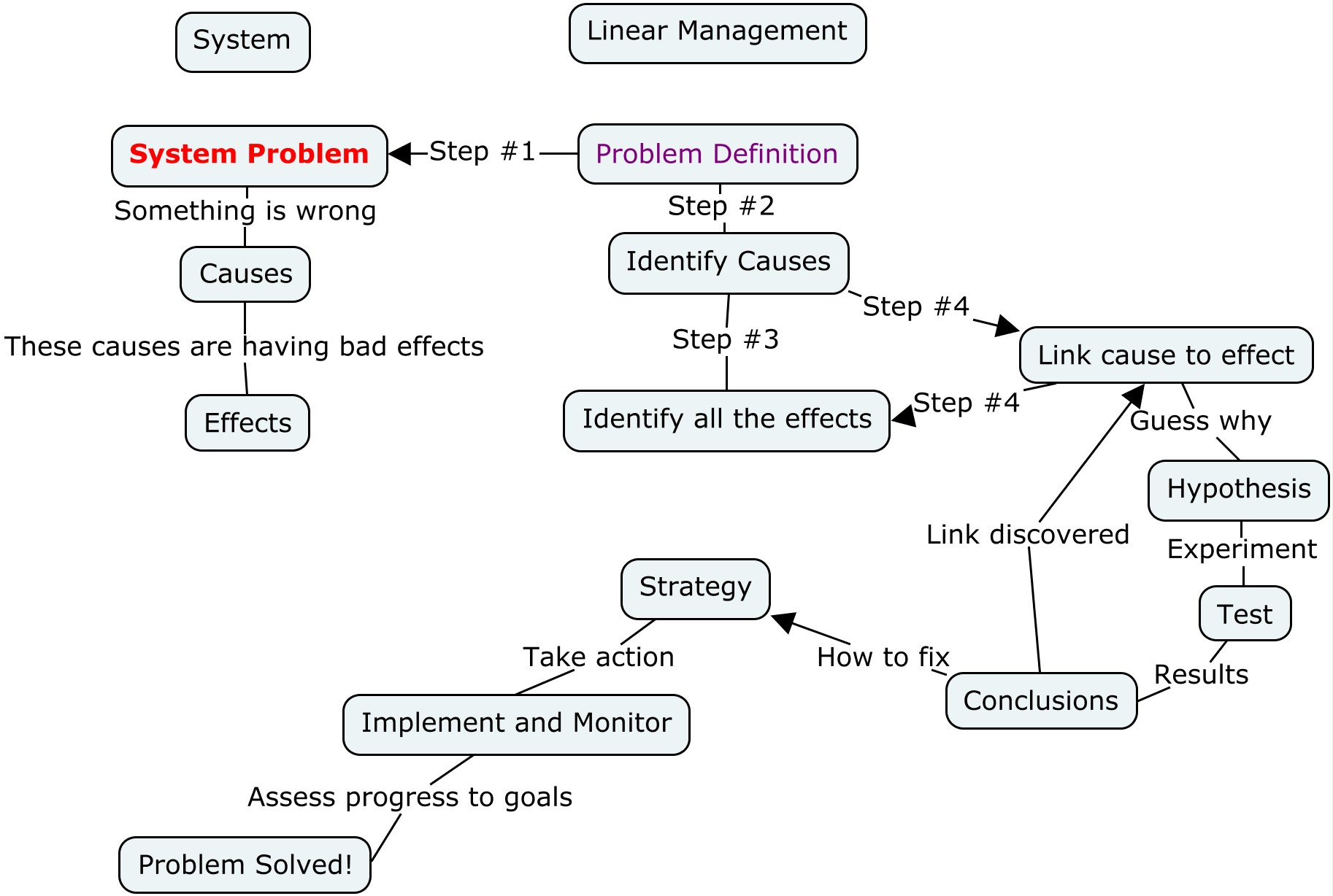

All of these problems can be solved using “linear” management techniques. Linear management of problems begins with defining the problem. Once the problem is defined, it can be broken down into elements that have causes. Root cause analysis can be applied here (including Lean Six Sigma techniques). Each cause has one or more effects that happen in an orderly sequence and we can find the links by collecting data. Then from this information management tests various ideas or hypotheses to come up with strategies to fix the system. The actions flowing from the strategies are implemented and monitored to correct the system.

Linear Problem Solving

Example of a route map through a wicked problem

Lean Six Sigma

Lean Six Sigma is actually a merging of two separate methodologies that deal primarily with process improvement as they relate to business practices and customer satisfaction. However, many of the tools that are used in Lean Six Sigma can be applied to solve problems of an intractable nature (ergo "wicked problems"). Lean is a business strategy based on satisfying the customer by delivering products and services that are just what the customer needs, when the customer needs them, in the amount required, at the right price, while using the minimum of materials, equipment, space, labor, and time. Lean practices enable an organization to reduce its development cycles, produce higher-quality products and services at lower costs, and use resources more efficiently. Six Sigma, on the other hand, is a strategy for an organization to manage by FACTS and DATA. It attempts to identify the core processes and root causes that drive an organization's strategic business objectives.

Using Focus Groups

“Wicked” problems such as global warming, drug abuse and terrorism often contain a mix of technical, economic, social, and political elements, making them extremely difficult to solve. Such problems are usually ill defined and often set aside as “too hard to do.” A general problem-solving method—labeled “the wicked problem approach”—can be used to effectively address such problems.

The approach described below was used to determine how cities could best respond to biological terrorist attacks. This approach is unusual in wicked problem approaches in that it does not use stakeholders, but instead uses people who do not have a strong personal interest in the subject. The idea is to arrive at an objectively determined best solution in the form of strategies that are then made available to stakeholders to implement using either a mapping or a Lean Six Sigma technique for implementation.

Moving from vision to strategic solutions using focus group analysis